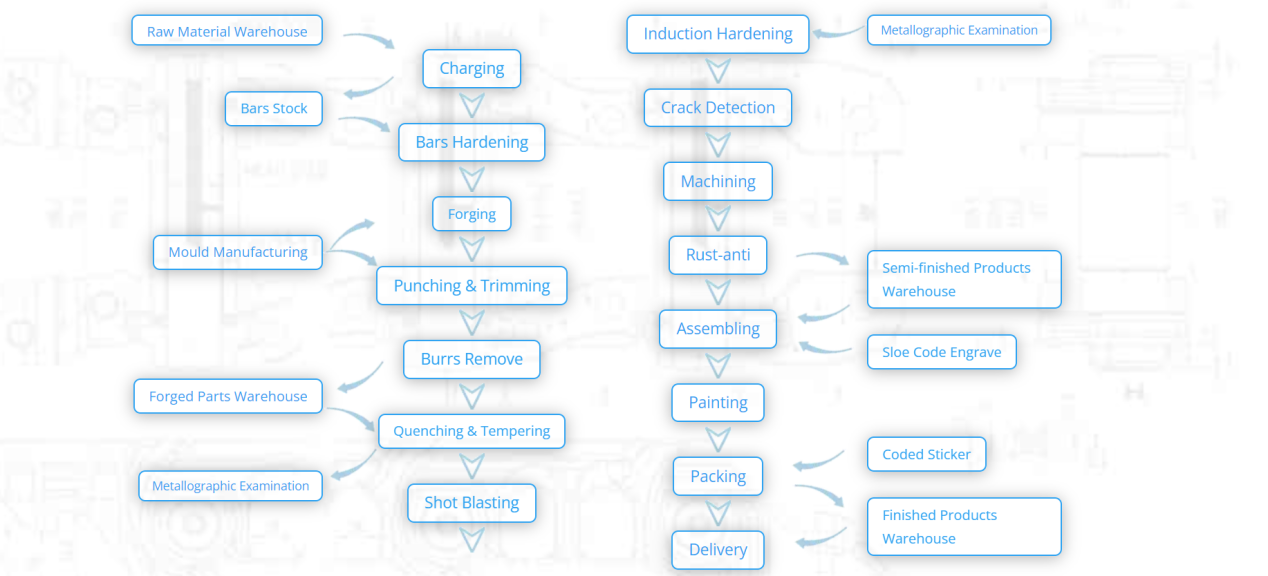

Excavator and Bulldozer Track Chain Production Process

How to judge the quality of a track chain? Just looking at the surface is not reliable. The systematic production process and strict inspection system are the guarantee for the production of high-quality track chains.

GT makes the production process transparent, allowing customers to understand the overall production process of the track chain, so that customers can use it at ease. Truly become a reliable supplier partner for customers

|

Description |

|

Surface hardening method |

Surface hardness(HRC) |

Low Material hardening method |

Material hardness(Hrc) |

Hardening depth(mm) |

Low Material (China) |

| Track pin | For bulldozer | Medium frequency hardening | 55~59 | Quenching and Tempering | 31~37 | P=171~190 3.0~5.0 P=190 4.0~6.0 | 40Cr |

| Track pin | For excavator | Medium frequency hardening | 55~59 | Quenching and Tempering | 31~37 | P=171~190 3.0~5.0 P=190 4.0~6.0 | 40Cr |

| Track bush | For bulldozer | Medium frequency hardening | 54~58 | Quenching and Tempering | 28~38 | P=171~216 3.6~5.0 & 2.7~4.0 P=228 4.7~6.2 & 3.0~4.7 | 40Cr |

| Track bush | For excavator | Medium frequency hardening | 54~58 | Quenching and Tempering | 28~38 | P=171~216 3.6~5.0 & 2.7~4.0 P=228 4.7~6.2 & 3.0~4.7 | 40Cr |

| Track link | For bulldozer | Medium frequency hardening | 50~56 | Quenching and Tempering | 33~38 | P=171~175 5.0~10.0 P=190~216 7.0~12.0 P=228 11.0~15.0 | 35MNBHS |

| Track link | For excavator | Medium frequency hardening | 50~56 | Quenching and Tempering | 33~38 | P=171~175 5.0~10.0 P=190~228 7.0~12.0 | 35MNBHS |